Automatic filling solutions for fluids

TEI can supply aeronautical maintenance professionals (MROs) with ready-to-use fluid filling benches and stations.

Our stations have been developed in partnership with MRO workshops to meet users’ specific needs as closely as possible.

The equipment presented is standard, compatible with different fluids (Gases: Nitrogen, Oxygen, Helium / Liquids: CO2, Water) but can be adapted to your specific needs.

TEI offers solutions including :

- Fluid treatment upstream of the filling system (expansion, excess pressure and filtration).

- Filling processes with pressure and/or weight set points incorporating associated instrumentation (pressure sensors manufactured by TEI, precision digital scales).

- Pressure regulation devices to generate a progressive and regular pressurisation, independent of the flow rate or volume to be filled, and able to adhere as closely as possible to the recommended filling curves.

- Monitoring of cylinder temperature during filling, with built-in safety in the event of overheating, and the possibility of correcting the filling setpoint according to cylinder temperature.

- Process automation with user-friendly HMI, ensuring fast and safe filling.

Our solutions designed by our team of engineers for these applications include:

- N2 & CO2 filling station qualified for evacuation slide cylinders on aircraft, with cylinder filling in liquid (CO2) and gaseous (N2) phase

- Automatic oxygen cylinder filling station (also suitable for medical applications) with single or multiple filling channels.

- Pressure booster station compatible with Oxygen, Nitrogen, Helium (others: please consult us) with buffer frames to ensure a stable supply upstream of the filling system.

- Inflation bench for aircraft wheels with semi-automatic generation system and secure inflation cage.

The strengths of the automatic oxygen cylinder filling station and the N2 and CO2 filling bench are:

- Management of several types of cylinders

- A precise, automatic filling process

- Options and upgrades available: the automatic oxygen cylinder filling station can, for example, be coupled with the oxygen booster station (recommended for filling several cylinders)

Our added value consists in:

- advising you on the most suitable test bench for your application, including CMM analysis.

- supplying a turnkey solution including installation, commissioning and user training.

- providing preventive and corrective maintenance for the test bench, either on site or at the factory.

Choose efficient equipment designed by specialists to meet your professional requirements.

Our flagship product

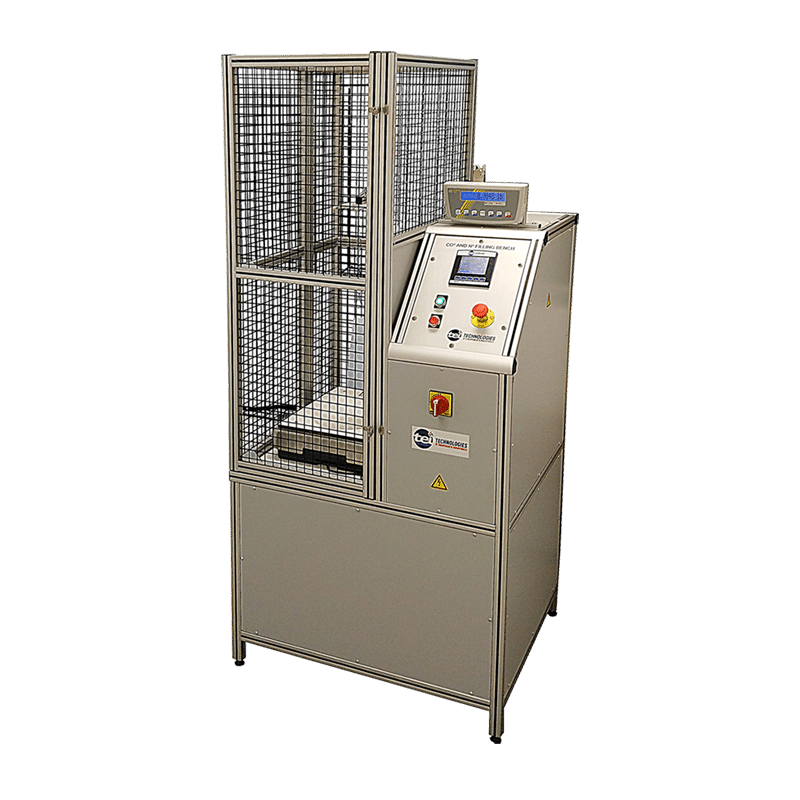

Filling bench CO2 and N2

The N2 and CO2 filling bench is adapted to MRO workshops and enables the automated (or semi-automated) filling of slide cylinders with gaseous nitrogen (N2) and liquid carbon dioxide (CO2) according to the manufacturer’s specifications (qualified for Airbus A320 slide cylinders).

The strengths of this equipment are:

- Full automatic filling process, managed by a PLC

- Possibility of integrating options such as an additional filling station and integrated cooling system.

Key words: Evacuation slide cylinders, CO2 / N2 filling

OTHER PRODUCTS RELATED TO THIS SOLUTION

OTHER SOLUTIONS

FOR TORQUE WRENCH

Read more about it

HIGH PERFORMANCE REGULATION

Read more about it

CYCLIC PRESSURE TESTING

Read more about it

FOR OXYGEN TESTING

Read more about it